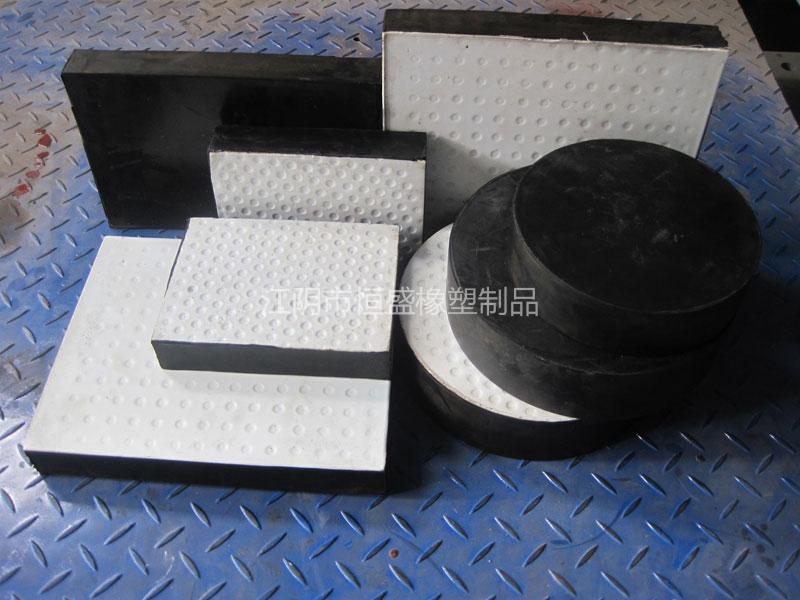

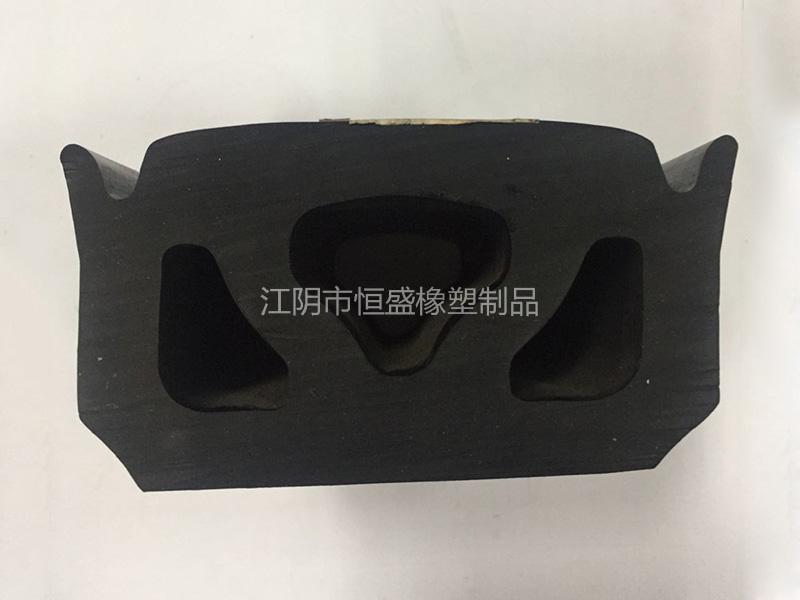

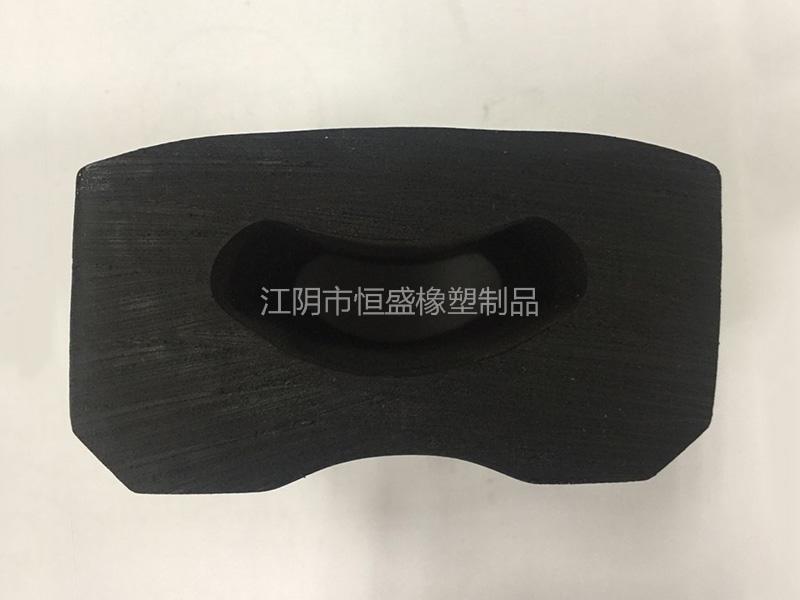

Tapered rubber fender

Classification:

Case Details

Features of tapered fender:

Tapered rubber fender is the third generation of drum rubber fender. It adopts a new structural design of cone rubber body and front steel frame, which makes the fender design compression deformation from52.5% increased70It has become one of the best rubber fenders today. Its appearance can make the design of wharf structure lighter and reduce the cost of wharf engineering. It is an ideal substitute for super drum rubber fenders.

It has been ten years since the advent of cone-shaped rubber fender, and the use of cone-shaped rubber fender in design has become a new trend in today's dock design and represents a new level of dock fender design.

1Compared with the super rubber fender of the same specification, the energy absorption is nearly doubled.

2In the case that the reaction force and absorption energy of the product are similar, the small-size cone rubber fender can replace the large-size super drum rubber fender, and it can be used.800HCone Fender Replacement1000HFenders to reduce the cost of the dock project.

|

Model specifications |

Design compression deformation |

reaction force |

Absorb energy |

Product height ratio |

Remarks |

|

1000HSuper Drum |

52.5 |

445 |

195 |

1 |

standard reaction force type |

|

800HTaper |

70 |

450 |

189 |

0.8 |

standard reaction force type |

3Inclined berthing of the ship(10°The following)performance is basically not reduced.

4The front edge of the fender is provided with a punch plate.(Steel frame), thus greatly reducing the surface pressure acting on the ship's side plate, according to the need, the surface pressure can be controlled25t/m2The following is particularly suitable for large ships berthing.

5Installation of ultra-high molecular polyethylene in front of the anti-collision plate(PE)The board can reduce the friction coefficient between the ship and the fender.(0.2The following), the shear force generated by the fender when the ship is berthing(Horizontal force)greatly reduced, thereby increasing fender life.

6The anti-collision plate generally adopts a closed structure, with high strength and good corrosion resistance.

7Because the fender is not in direct contact with the ship, it has the advantages of no wear and long service life.

Scope of application:

1Suitable for wharves requiring low reaction force and high absorption energy.

2It is especially suitable for docks with low surface pressure requirements for berthing ships.

3, suitable for oil terminals, container terminals and other large terminals and offshore open berthing.

4All occasions where super drum type fenders are used.

Keywords: Tapered rubber fender

Other Products

Product Consulting